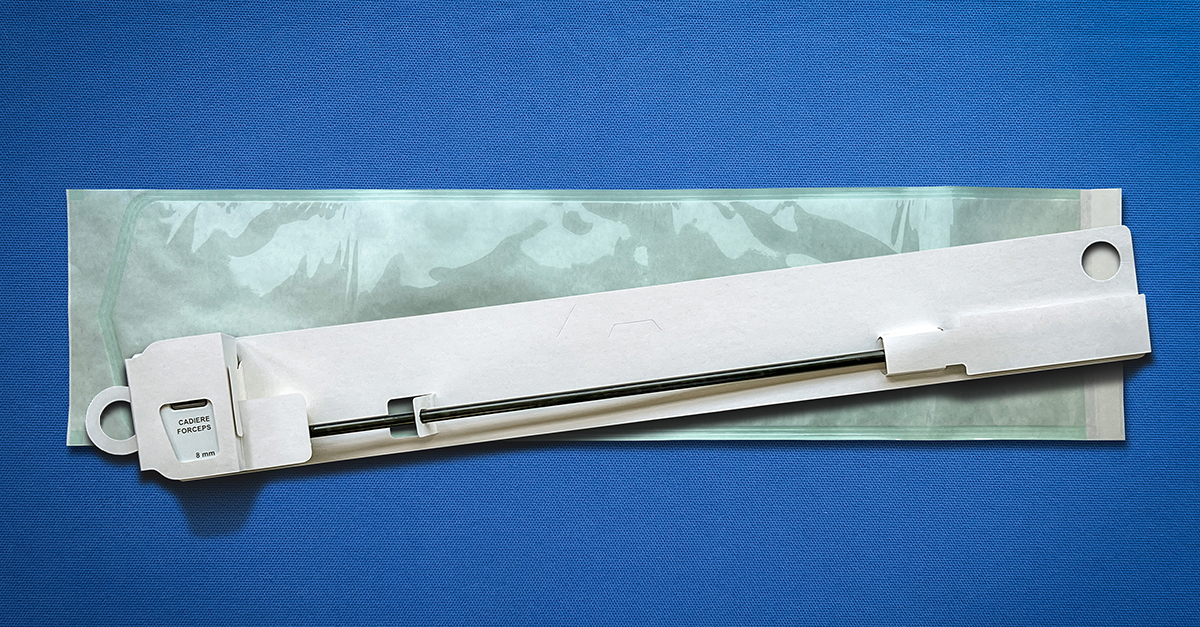

The SterileBits Robotic Arm Instrument Protector is an elegant but revolutionary innovation that allows for aseptic presentation of robotic surgical instruments to the sterile field.

SterileBits introduces the Robotic Arm Instrument Protector, a product that promises structure, consistency, and ease-of-use for nurses and clinicians handling surgical equipment every day.

Standing alone as the world’s first instrument protector card of its kind, this product addresses critical issues that leave clinicians and patients alike wondering why someone didn’t invent it before.

One of the greatest concerns that co-founders Guy Phipps, RN, BSN, MBA, CNML, and Craig Ford recognized and addressed with this innovative new surgical instrument accessory is that there is no established industry standard for the storage and packaging of robotic surgical instruments. Phipps and Ford leveraged their extensive experience as perioperative professionals to personally identify common challenges associated with maintaining the sterility of surgical instruments.

The Robotic Arm Instrument Protector has one specific job — to safeguard surgical instruments during sterilization, transport, and delivery to the operative field. Without an instrument protector card, robotic instruments are at risk of damage or compromising the sterile barrier if they pierce the peel pouch at any time during the multiple touchpoints they pass through before reaching the operating room (OR).

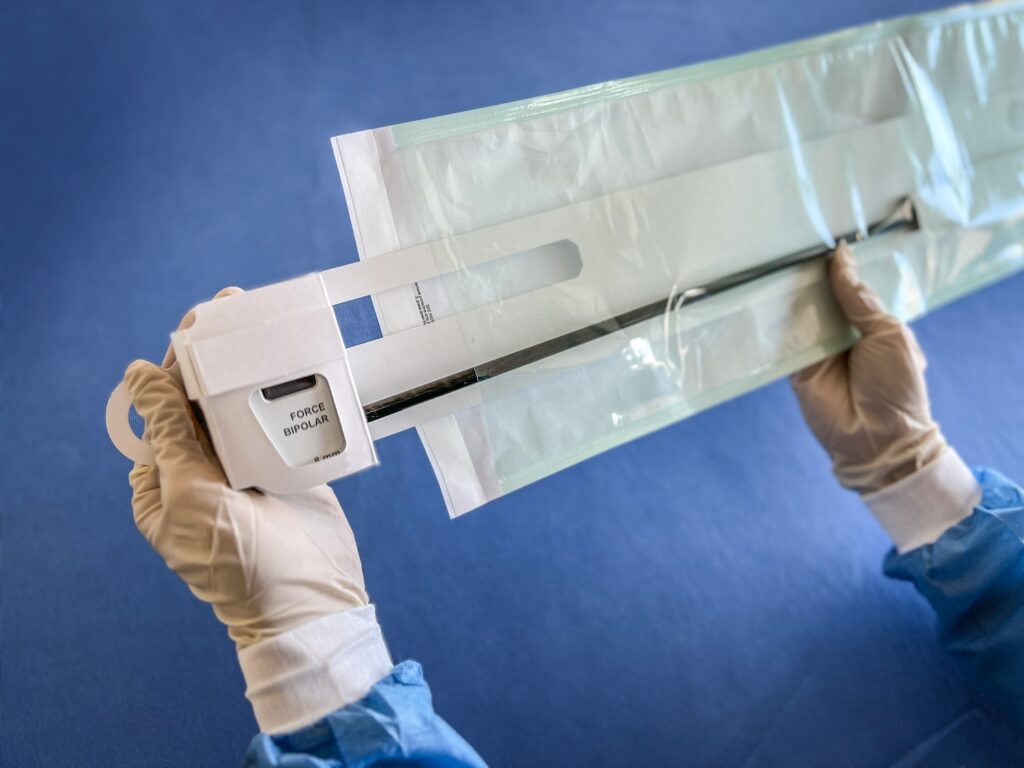

According to the National Library of Medicine, the contamination rate of surgical devices is significantly correlated to the way in which a nurse or technician opens a package and retrieves a device. Additionally, if there is any breach in the integrity of the pouch during transportation, the instrument must undergo re-sterilization before use. This process results in both financial loss and the depletion of the instrument’s finite number of useful lives.

The structure of a sterilization card prevents surgical and robotic instruments from piercing its packaging in this way. With this in mind, SterileBits developed a product that suits many robotic instrument sizes, ensuring that a package’s integrity is not compromised due to incompatible sizing. There are two retrieval rings (one located on each end of the card), allowing surgical technicians to smoothly retrieve the instrument from its package in a non-invasive manner.

Given an instrument protector card’s critical role in patient safety and nurse efficiency, it’s reassuring that a solution has emerged to directly address these concerns.

The SterileBits Robotic Arm Instrument Protector is produced with 100% recyclable and renewable materials, no ink, and no coatings. It is designed to make the storage and retrieval of a robotic or surgical instrument more efficient and effective when it arrives at the point-of-use. It only takes an average of 36 seconds to place a robotic instrument onto an instrument protector or sterilization card once someone learns how to do it correctly. It takes less time to retrieve it from the peel pack safely.

Spending these 36 seconds in preparation can save a perioperative nurse countless minutes that they may then spend obtaining a replacement instrument or tearing down a contaminated sterile field due to a lack of user-friendly packaging. Even more, it can help protect patients against surgical site infections (SSI’s), which make up about 20% of healthcare-associated infections, according to a review cited in Packaging Digest.

To learn more about instrument protectors by SterileBits, click here.

To read more articles similar to this one, visit the blog on www.sterilebits.com.

To stay up to date with SterileBits in real time, follow SterileBits on LinkedIn.