There are many right ways to build a sustainable product, and many wrong ways, too. In developing SterileBits instrument protector cards, co-founders Craig Ford and Guy Phipps have found that thinking “big picture” combined with a little cleverness often leads to the “greenest” outcome.

Sustainability seems to be a word that is on everyone’s tongue these days – and for good reason. To put it grimly, according to the National Oceanic and Atmospheric Organization (NOAA), the amount of carbon dioxide in the atmosphere has risen by 25% since 1958 and by about 40% since the Industrial Revolution, droughts are becoming more and more common, and sea level rise has accelerated from 1.7 mm/year throughout most of the twentieth century to 3.2 mm/year since 1993.

Though it perhaps has a more noble cause than many other agents of environmental decay, the healthcare industry is anything but exempt from culpability. According to the Association of American Medical Colleges (AAMC), hospitals and labs emit 4.4% of the world’s greenhouse gas emissions and are responsible for more than 5 million tons of waste each year.

This knowledge and more has sparked a surge of companies across industries pushing products with “green-er” initiatives, such as claims of using less plastic than before.

While any effort of “going green” is worthwhile, this is one of those topics that is important to overthink. Taking the most obvious measures – recycling, reducing plastic, using reusable materials – is great, but it isn’t enough. So, the question becomes: How do we adjust the entire system – from material collection to production to consumption to waste – so that everything we do is as sustainable as possible? In other words, how can we do what we do as humans more thoughtfully, so that we can do it for a long time without hurting the environment our ourselves?

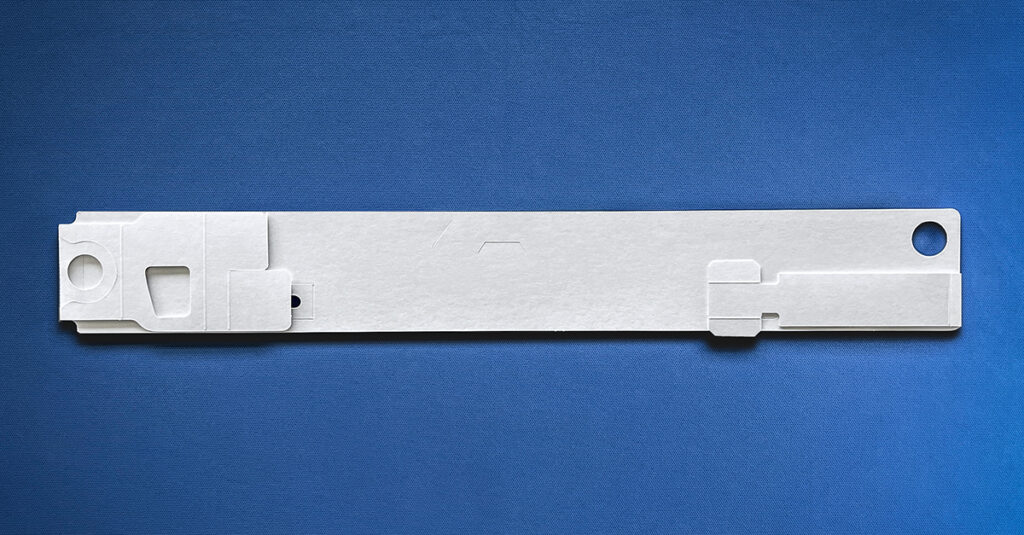

Those were the questions running through the minds of co-founders Guy Phipps, RN, BSN, MBA, CNML, and Craig Ford when they invented SterileBits instrument protector cards.

“In my clinical role,” said Phipps, who is the Director of Perioperative Services, Cath Lab, GI & ASC Administrator in Hawaii, “I’ve been known to champion green initiatives. When the hospital receives a product in a plastic pack, I wonder: What do I do with it? It may go into clean waste, but it’s not going to get recycled. How do you handle all of this extraneous waste that’s out there? I believe things should be in simple packaging. I really don’t like plastic.”

So, when developing sterile instrument protector cards, Phipps and Ford began with the question of sustainability. To get to the root of the problem, they dug deep. What would actually allow hospitals to produce less waste while achieving high standards of sterilization and keeping patient and clinician safety and ease at the forefront?

Here’s what they found:

Create a 100% recyclable product – “When it comes to hospital waste, a lot of the clean material can be recycled or reprocessed, but if you put material into a red bag, it goes for burning and landfill, plus it costs you four times as much to get rid of it,” said Phipps. “So, the idea is: How can we process things out of the hospital in the cheapest way for the hospital and the environment?”

The answer here was simple: create a 100% recyclable product.

Organic ink (even better, no ink) must be on the protector card – In order to create a truly recyclable product, it must include no ink. “At first, we tried to put organic inks on the card, but that created problems,” said Phipps. “So, from there we decided there must be no ink on the card. All the labeling is on the box and the packaging, and that was a very deliberate decision. Even the inks that are on the outside of the boxes are organic.”

Produce with 100% renewable energy credits (RECs) – Of course, waste and pollution are not only generated by disposing of a product itself. A truly ‘green’ product reduces waste and energy consumption from the very beginning – production. Phipps and Ford found that a great way to minimize the use of fossil fuels and other unsustainable energy sources is by manufacturing the product using renewable energy credits (sometimes referred to as renewable energy certificates). According to the United States Environmental Protection Agency, RECs are issued when one megawatt-hour (MWh) of electricity is generated and delivered to the electricity grid from a renewable energy resource.

Minimizing the need for re-sterilization also reduces the use of resources needed to re-sterilize – After a sterile instrument is used, “It’s not just wiped off and put in a bag again. It has to go through a whole wash process,” said Phipps. “For that, we have to use water, chemicals and all sorts of other resources. There’s a whole gamut of things that you could scrutinize from an ecology point of view.”

That is yet another reason why it is so important to preserve instruments that have been sterilized. If gravity and momentum cause a robotic or hinged instrument to puncture its peel pack, that instrument must be re-sterilized using all of those resources – water, chemicals, etc. When an instrument is protected with an instrument protector card, this use of resources can be avoided.

Protect what you have; preserve the life of your instruments – When you have to re-sterilize a reposable instrument that hasn’t been properly protected before use, you end up wasting one of a finite amount of useful lives of that instrument. Not only can this be extremely financially costly (for robotic instruments, one useful life can range from $250 to $2,500 in value), the Earth also bears the consequences. The more we protect the instruments we have and get as much use out of them as possible, the less instruments will need to be produced in the long run. No one wants to see precious materials, be it aluminum, steel, copper, or even plastic, become waste before they need to be.

SterileBits: Treasure Your Instruments, Preserve Our Earth

For more stories similar to this one, visit the SterileBits blog or follow SterileBits on LinkedIn.

Questions about instrument protectors by SterileBits? Contact us or visit the products page to learn more.