Sterilization and instrument protector cards by SterileBits provide structure, consistency, and sustainability for clinical environments. Because the instrument protector card is a first-of-its-kind innovation, questions abound. Here is a breakdown of our most frequently asked questions (FAQs) about solutions for instrument protection by SterileBits.

Think about the challenges you or your colleagues face every day when it comes to handling sterile surgical and robotic instruments. Often, clinicians report challenges such as the possibility of the sterile barrier being compromised by the instrument penetrating the peel pouch, risking contamination when reaching into the package, or being unsure of the integrity of sterile instruments that have passed through many touchpoints prior to reaching an operating room (OR).

Though these are small challenges within a much bigger process, inconsistencies along these touchpoints add up. While one such consequence is frustration, another might be wasting one of a finite (not to mention, expensive) number of useful lives of an instrument, or worse, the use of a contaminated instrument on a patient.

That’s why SterileBits instrument protector cards were created with the goal of addressing the most frequent and significant challenges that come with maintaining the sterile barrier of surgical instruments and eradicating those challenges from your (already long) checklist of concerns. Co-founders Guy Phipps, RN, BSN, MBA, CNML, and Craig Ford identified these challenges themselves from their own work as perioperative professionals. They used their understanding of the intricate nuances of surgical procedures and technology to create a product in good faith that genuinely solves many problems for surgical teams in the operation room. They understand that the problems that affect nurses, technicians, and patients should be top priority for medical device development.

The OR is no place for uncertainty. So, today we are tackling your uncertainty when it comes to instrument protector cards by SterileBits. If you are wondering: How does this product actually solve my problems as a clinician? Is it more expensive to use? Is it worth it? Is it sustainable, and more – you are in the right place. Here are some of the most frequently asked questions about instrument protector cards as well as insight into the nature and benefits of the product.

Why should I use an instrument protector card? What’s the use?

There are plenty of reasons why you should use an instrument protector card for your robotic and hinged instruments. Long story short: relying solely on a peel pouch or rubber tip protector is just not good enough. A flimsy or small barrier does not actually protect the mechanics of your instruments, which can be small but intricate and more than worthy of protecting. Not to mention, placing a snug rubber tip on an instrument might actually reduce the surface area that is exposed to sterilant, leaving it unsterilized.

Think about it. What are you really trying to achieve with your instrument protectors? More often than not, an instrument protector card will serve all the functions you want it to, and more, where other kinds of protectors unfortunately fall short.

“It happens quite often that people will say to me, ‘We just stick a bit of peel pouch over the tip, or we put a rubber tip on the end to protect it,’” said Phipps. “My response is always, ‘But what are you really protecting when you do that? Because you’re not really protecting the mechanics. Especially for robotic instruments.’”

Is it more expensive to use an instrument protector card?

No. Especially when it comes to protecting the useful lives of your instruments. If there is any lack of integrity in the pouch that transports the instrument (maybe the instrument punctured the pouch, or a rubber tip was used that didn’t allow for the thorough sterilization of the entire instrument, for example), then it must be re-sterilized without being used. This results in a loss of one of a finite number of useful lives of an instrument. When you break it down, each useful life of an instrument, especially robotic instruments, can cost hundreds of dollars.

The fact is: it’s less expensive to use a SterileBits instrument protector card than it is to use a rubber protector or a protector card by any other original equipment manufacturer (OEM).

“You would think that a card like this would cost more than a little rubber plastic tip. Not true. The cost is one of the biggest and first things that we looked at when we first started developing this product,” said Phipps.

Does it take more time to use an instrument protector card? How much?

Yes, but not much. Trials show that it takes an average of 36 seconds to place a robotic instrument onto an instrument protector or sterilization card once someone learns how to do it correctly.

“The Sterile Processing Department (SPD) might say, at first, that it takes an extra few minutes to place an instrument in a sterilization card,” said Phipps. “Craig [Ford] and I know that if you start playing with it and you get adept at it, you can do it in seconds. And it is so worth it for the end users — the clinicians.”

Besides, settling for the quicker option does not always guarantee that the instrument will be sterilized properly, and adding those few extra seconds of preparation could mean the difference between an instrument that retains its state of sterilization across touchpoints.

What problems do instrument protector cards solve?

Problem 1: Currently, in the industry of surgical technology, there is no industry standard for the storage and packaging of robotic and surgical instruments. Some go in trays, others in wraps, clear plastic pouches, stacked in bins, hanging on carts, boxes, etc. By providing both structure and visibility, instrument protector cards by SterileBits standardize and simplify methods of organization of sterile instruments. Phipps and Ford hope and foresee a day in which sterilization cards will be widespread throughout the industry so that storage is seamless and organized across hospitals and SPDs.

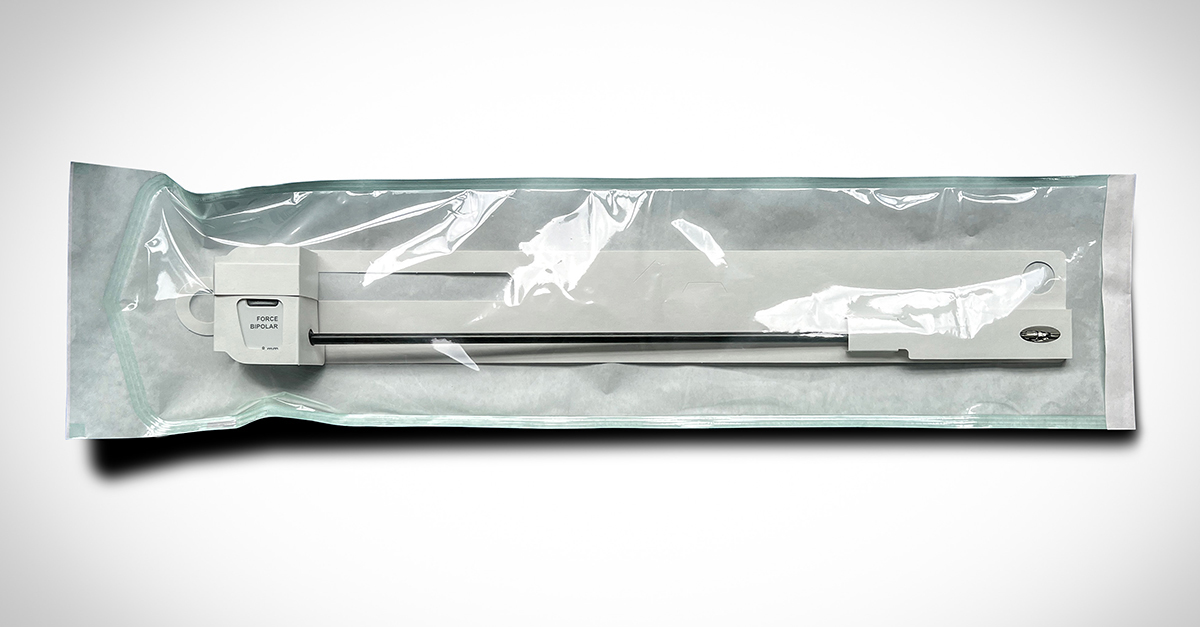

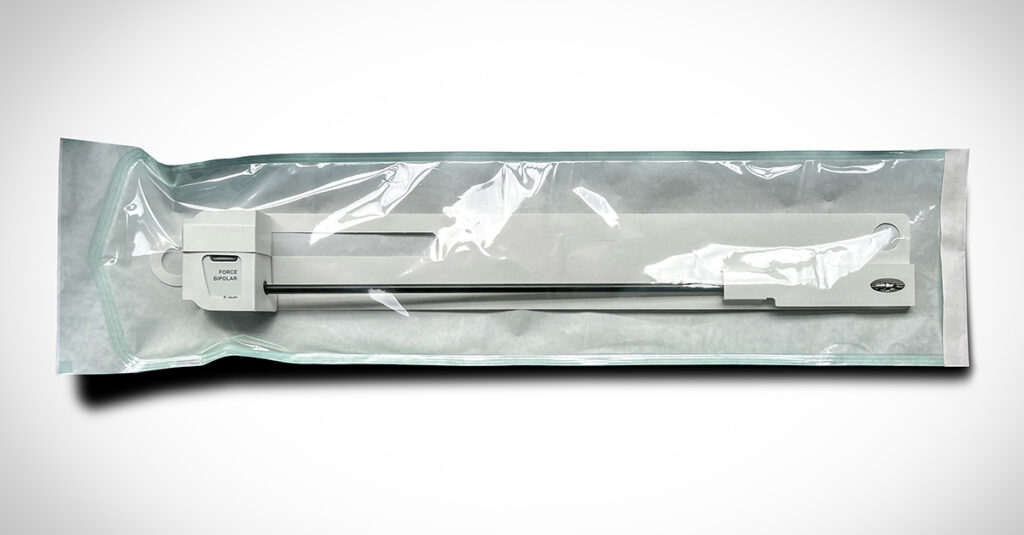

Problem 2: According to the National Library of Medicine, the contamination rate of surgical devices is highly correlated to the way in which a surgical technician opens a package to retrieve a device. To combat this threat, a SterileBits protective card has two retrieval rings located on each end of the card, making for a seamless and non-invasive retrieval of the instrument from its package.

Problem 3: The structure of a sterilization card also prevents surgical and robotic instruments from puncturing its packaging — a common occurrence that compromises the integrity of the package and renders it unusable.

Unlike other protective cards with a floppy structure, SterileBits protective cards are designed to accommodate various sizes of instruments more effectively. SterileBits acknowledges that existing products overlook the fact that robotic instruments come in diverse lengths and shaft sizes. That’s why SterileBits developed a product that suits many robotic instruments, ensuring packaging integrity and preventing any sharp tips from puncturing the packaging due to incompatible sizing.

Are SterileBits instrument protector cards made sustainably?

Yes. All SterileBits products are produced with care and consideration for the environment and are made with 100% recyclable materials, no ink, and no coatings. So, after each use of a sterilization card, all you have to do it recycle it. “The less we as an industry can contribute to waste and landfills, the better,” said Phipps.

SterileBits: Defeat Uncertainty

Read more stories like this one on the SterileBits blog.

To find a distributor near you, click here.