Robotic and hinged instrument protectors by SterileBits ensure increased useful lives of instruments, consistency, and sustainability in clinical workplaces. Here’s how.

In a hospital setting, time is precious. Any behavior or product that promotes efficiency or accuracy during the day is of benefit. It means healthcare professionals can move through procedures swiftly and efficiently. It also means they can stay focused on the patient. Zooming out to the administrative side of things, it also means saving money and resources for the hospital in the long run.

When it comes to robotic instruments, reprocessing and replacing them before their useful life is a common pitfall that falls on the shoulders of hospital administration and perioperative nurses alike. Every sterilization cycle of an instrument has a monetary value, and it’s all too common for that value to be compromised by flimsy peel packs that can damage robotic arms or hinged instruments — or worse — compromise the sterile barrier. Even at their best, peel packs offer little uniformity to perioperative services.

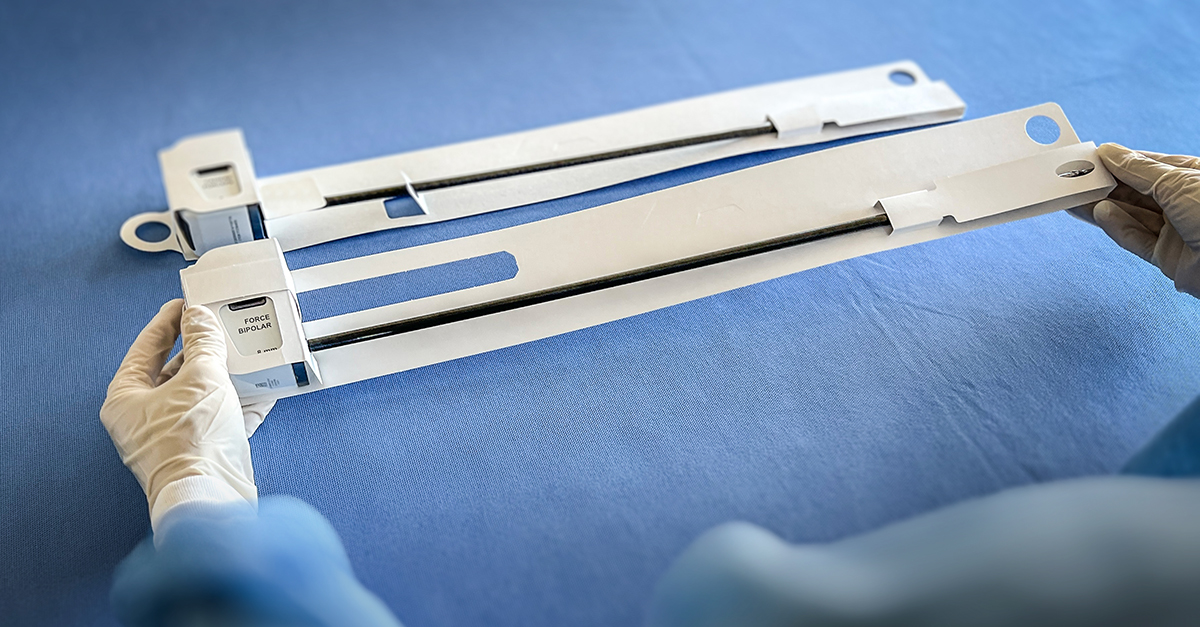

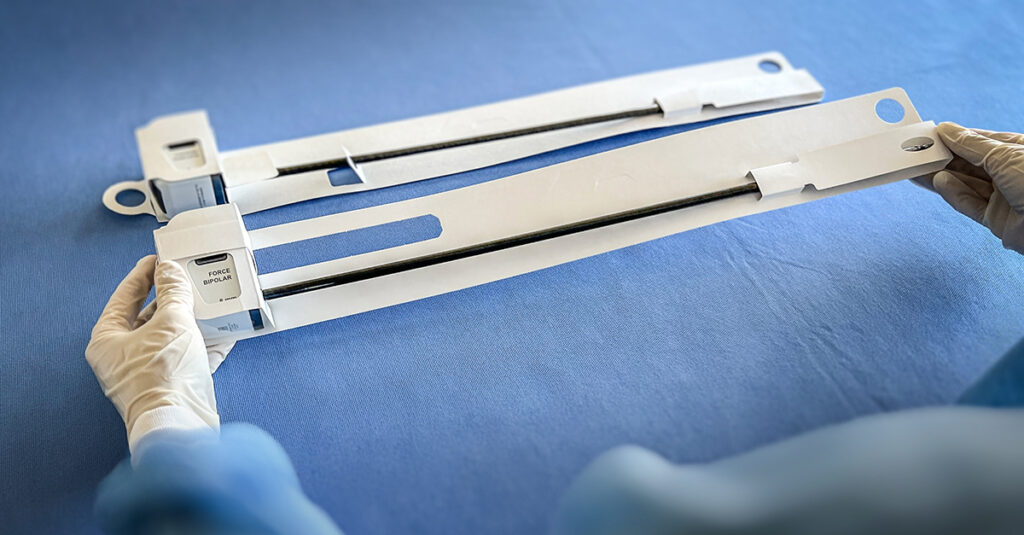

Driven by the promises of structure, consistency, and doing the very best by people who use or manage surgical equipment every day, SterileBits designed the world’s first instrument protector cards with a single purpose in mind: to safeguard surgical instruments during sterilization, transport, and delivery to the sterile field.

As with any innovation in the sterile processing world, questions are normal. In fact, they are encouraged.

That’s why the co-founder of SterileBits, Guy Phipps, RN, BSN, MBA, CNML, Director of Perioperative Services, Cath Lab, GI & ASC Administrator is here to provide answers to your most pressing questions regarding the impact, use, and benefits of instrument protectors by SterileBits.

Q: What makes SterileBits instrument protectors stand out against other products of this kind?

Phipps: There is only one other regularly used product on the market of any significance, the 3M Attest, and its flimsy nature is prone to tearing off, leaving shards of glue everywhere. You also can’t use it as a carrier for instruments. The beauty of the SterileBits instrument protector is that it has no other components to it. It guards your instrument with its sturdiness. It is designed to function as a carrier, allowing scrub personnel to extract the item without having to reach deep into the sterile pouch to retrieve it.

Phipps expands on this topic in episode 67 of the Ask the Educator podcast by Healthmark Education. Click here to listen to the podcast on YouTube.

Q: What are the advantages of extracting a robotic instrument from its packaging without reaching into the package itself?

Phipps: Routinely, when you open a sterile peel packet, the instrument is subject to gravity and momentum, which can cause creasing or crushing. When the instrument is attached to the SterileBits instrument protector card, it is secured in its position and therefore safeguarded from that risk. Additionally, as sterile personnel, you don’t want to be blindly reaching down into the packet. That could compromise the sterile barrier. That’s why we designed our protectors such that the ring automatically appears and there is no danger of contaminating oneself. You can just retrieve the instrument and go from there.

Q: How do SterileBits instrument protectors protect a hospital’s investment?

Phipps: Quantifiably speaking, the cost of using standard instrument protectors might seem minimal, just a few cents each time. However, every time an instrument penetrates a packet or renders a peel pack compromised, you must reprocess that instrument. This can be quite costly in its own regard. The SterileBits protector card eliminates the possibility for the instrument to penetrate that packaging and therefore its integrity is guaranteed. The more you can trust that your surgical equipment is protected, the more time, and money, you save in the long run.

Q: What has been the general feedback on instrument protectors by SterileBits?

Phipps: At all of the places where we’ve run trials, people love it. They see the advantage of it. Some of the challenges that came up at first was that sterile processing technicians felt that it took longer for them to prepare the card and put the instrument in, but once they got used to it, it took a matter of seconds. 36 seconds, in fact. It’s all about the greater good that the card provides. It’s bringing to the table what the clinicians need, and everybody loves the fact that you don’t have to reach your hand into the package. You can simply pull it out and the instrument is ready to go.

Q: What are the consequences of assuming an instrument is sterile when it might not be?

Phipps: Hopefully it’s caught before the instrument reaches patient use. If it goes undetected, then we have to do full disclosure. We have to do antibiosis, inform infection prevention, and tell the patient. What comes with that is a lot of psychological distress to the patient, and that’s something we also want to avoid. The outcome of using instrument protectors by SterileBits is prevention rather than consequences.

Q: What are the main advantages of using the SterileBits product?

Phipps: From a clinician’s point of view, there’s a wealth of advantages. Typically, when instruments are stored in bins, clinicians have to ruffle through a whole bunch of them, which can crease packaging and compromise the integrity of the instrument. Instead, the SterileBits card has more structure, which allows for more uniformity while ensuring a sterile product.

When it comes to robotic protectors, there’s hardly a standard way to properly hang and store them. A lot of people hang them, but with that practice one must consider the protector’s weight and the threat of the tip puncturing the package. By using a protector card that provides structure for the instrument, the worry of damage to the packaging is eradicated because the variable of gravity causing trouble with storage is out of the picture.

Most importantly, SterileBits instrument protectors allow for consistency in practice. Each healthcare professional in the Sterile Processing Department (SPD) might wrap something slightly different, and they might have different lengths on their packages. The card in which our instruments arrive allows for consistency in how the instruments are handled, packaged, and delivered to the clinical area. This consistency is important because it curates confidence in the system – you want to know that your instrument processes are reproducible and offer the same sterile service time and time again.

SterileBits instrument protectors are also sustainably made and recyclable. The product is made of simple cards that can be recycled with no danger to the environment. Every other product of this kind on the market ends up getting thrown into the trash, and a lot of hospitals right now are really driving a green component to their practices. The less we can contribute to landfill and waste burning as an industry, the better.

SterileBits Instrument Protectors: Protect Your Hospital’s Investment, Improve the Working Lives of Clinicians

To learn more about the SterileBits product, click here.

To read more stories similar to this one, visit the SterileBits blog page.

Interested in bringing instrument protectors by SterileBits to your hospital or clinic? Click here to be in touch our distributors.