SterileBits was founded on the core belief that the instruments clinicians use every day should make their lives easier, not harder – and who is better to make that call than clinicians themselves?

In the medical device sphere, how often has an innovation originated with the question: How can we create a product that eliminates problems and makes the working lives of healthcare practitioners easier?

It has, to the detriment of the real professionals using medical devices each day, become common practice for registered nurses (RNs), physicians, and other clinicians to only be included in new product design once the device is nearly ready to hit the market. Then, new devices are released and pushed into the industry absent of the critical perspective of those who use the product each day.

While it may seem obvious that instruments and practices that support clinicians in their work will lead to better outcomes for patients, it’s not uncommon that the keen problem-solving abilities of perioperative professionals are exploited in favor of the administrative status quo.

That is exactly the cycle that co-founders Craig Ford and Guy Phipps, RN, BSN, MBA, CNML wanted to break when they created instrument protectors by SterileBits.

“These instrument protectors were designed and thought up by people on the inside — clinicians,” said Phipps. “It’s not just some idea that sales reps are trying to throw at clinicians without any real purpose. It’s just the opposite. We have intentionally created a product that can become a new industry standard because it’s been optimized to serve the best interests of anyone and everyone who comes into contact with it. The end users – clinicians – come first.”

It all started with a gap that Ford and Phipps identified in their work as healthcare practitioners. Now the Director of Perioperative Services, Cath Lab, GI & ASC Administrator in Hawaii, Phipps was working at a Level II Trauma Center in California, where Ford approached him with one of the first prototypes of a SterileBits instrument protector in 2020.

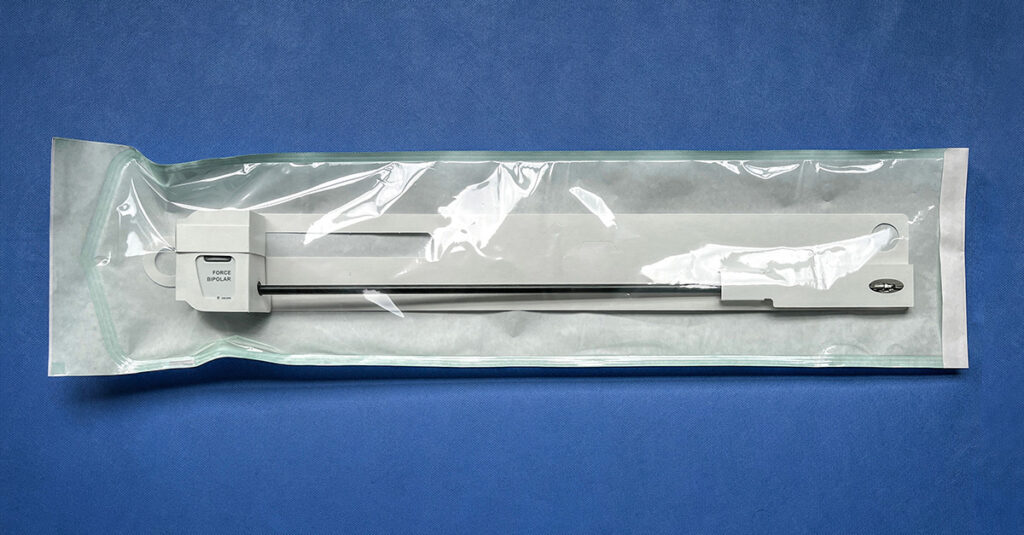

The product that Ford showed Phipps was a reusable sterile drill bit. Out of the whole design, one component caught Phipps’ eye more than the rest – the card that Ford had created to hold the drill bit. At the time of this meeting, Phipps had been unimpressed for some time with the instrument protectors on the market. The downfalls of the product, such as its lack of structure and susceptibility to puncturing the sterile barrier, hindered his practice every day. “What we should do is reinvent that product,” Phipps told Ford.

Instruments Made by Clinicians for Clinicians

Ford was inspired. After a brief intermission for reflection and ideation, the two reunited during a large parade that special forces threw outside the medical center to show support for healthcare workers, in the early days of the Covid-19 pandemic. With jet planes and firetrucks in full jubilance outside the hospital, Ford showed Phipps the updated instrument protector prototype. Phipps was invigorated. He felt full faith that this was a device that could really make his life, and the lives of his colleagues across the world, better.

“From my perspective on the inside as an RN,” said Phipps, “I know where and why the product makes sense. It solves so many little questions and issues that I had encountered every day for more than 30 years.”

After a few tweaks to the prototype, the founders sent it to Sterile Processing Departments (SPDs) across the country. Then, the founders brought it directly to clinicians. The goal was to make sure they didn’t miss anything and that each clinician would, without a doubt, feel that the product supported their practice.

“The robotic instrument protector card got validation when we started to give samples to clinicians and they came back to us and said, ‘This is really good. We really like this. It makes sense from our point of view,’” said Phipps. “Which was the goal all along.”

The main feedback the co-founders received from those early samples fell under four main umbrellas:

1. SterileBits Instrument Protectors allow for consistency (and certainty) in practice. The single biggest cause of peel pouch failure is the instrument itself puncturing the peel pack due to gravity and momentum. To combat this, instrument protectors by SterileBits come with a card that adds extra rigidity to the pack and places a barrier between an instrument’s delicate edges and the pack. This means the instruments are safeguarded against damage and breach of the sterile barrier. So, when it gets in the hands of a clinician, that clinician can be as certain as humanly possible that the instrument is sterile and ready for use.

“The product is designed to protect and ensure integrity — all the way from SPD to the operating room (OR). It can even protect against the gravity and momentum element when you’re trying to open it,” said Phipps. “It meets every little challenge along an instrument’s journey so it travels from point A to point B as an intact package.”

“Everybody wants confidence, right? If a product arrives and you are 99.9% sure that what you’re about to grab is in good condition to work, that’s what you want. You want certainty, and you want to know that you can consistently have that certainty,” said Phipps. “If you eat in a restaurant, the next time you go back and order the same meal, you want it to taste exactly the same. That’s what we need to be able to deliver to clinicians. When you’ve already got a patient on the table and are expecting to have surgery, you need to be able to trust your instruments.”

2. Clinicians don’t have to reach in the peel pack to retrieve the instrument. As sterile personnel, the last thing you want to do is reach down into a peel packet and risk contaminating yourself. That’s why the SterileBits card is designed to act as a carrier with a retrieval ring – so that scrub personnel can pull the item out of the pack without delving into the sterile packet to retrieve it.

“When you peel the packet, the ring automatically appears and therefore you have no danger of contaminating yourself. You just retrieve the instrument and go from there,” said Phipps.

3. It is survey compliant. When instruments undergo sterilization, the maximum surface area possible must be exposed to the sterilant. In the case of hinged instruments, this means that they need to be sterilized while open.

The structure of the SterileBits instrument protector card allows instruments to be supported and held open during and after sterilization. “That is also the reason why there is a fold instead of a pouch to stick the end of the instrument in. The fold allows sterilant to enter,” said Phipps.

The structure of the SterileBits instrument protector card allows instruments to be supported and held open during and after sterilization. “That is also the reason why there is a fold instead of a pouch to stick the end of the instrument in. The fold allows sterilant to enter,” said Phipps.

4. It protects the useful lives of instruments. If there is even a doubt about the integrity of a sterile packet, then an instrument must be resterilized without being used. This eliminates one of the finite number of useful lives for which the instrument was manufactured. When you break it down, the cost of one useful life in robotics can be anywhere from $250 to $2,500.

“When comparing the cost of a card to the worth of each use of a reposable instrument, a couple of dollars spent protecting that investment is great,” said Phipps. “Each time you sterilize, you lose a life. So, you only really want to use what you need.”

5. It’s sustainable. Protecting and optimizing the useful lives of instruments isn’t only beneficial from a financial perspective, it’s also a sustainable practice. The more we care for existing instruments, the less we need to integrate new ones into the fold. This creates less waste in the long run.

Not to mention, SterileBits sterilization cards are entirely recyclable and produced with 100% renewable energy credits.

Trust: Making the Invaluable, Tangible

All of this is to say, clinicians need and deserve instruments that they can trust. That is precisely the belief that compelled Phipps and Ford to turn the first-of-its-kind instrument protector from a design etched on a piece of paper to a product that can be found in hospitals around the world.

SterileBits: Learn More

To read articles similar to this one, visit the blog on www.SterileBits.com.

Questions? Contact us here.